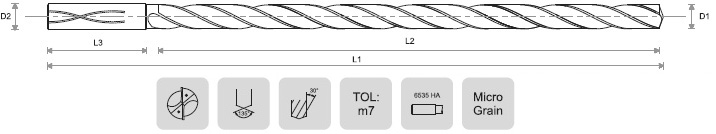

Solid Carbide Deep Hole Drills : BLD-94 L/D=30

| PRODUCT CODE | DRILL DIA | FLUTE LENGTH | OVERALL LENGTH | SHANK LENGTH | SHANK DIA |

|---|---|---|---|---|---|

| D1 | L2 | L1 | L3 | D2 | |

| BLD-94-030 | 3.0 | 100 | 140 | 36 | 6.0 |

| BLD-94-035 | 3.5 | 136 | 176 | 36 | 6.0 |

| BLD-94-040 | 4.0 | 136 | 176 | 36 | 6.0 |

| BLD-94-045 | 4.5 | 168 | 208 | 36 | 6.0 |

| BLD-94-050 | 5.0 | 168 | 208 | 36 | 6.0 |

| BLD-94-055 | 5.5 | 200 | 240 | 36 | 6.0 |

| BLD-94-060 | 6.0 | 200 | 240 | 36 | 6.0 |

| BLD-94-065 | 6.5 | 232 | 272 | 36 | 8.0 |

| BLD-94-070 | 7.0 | 232 | 272 | 36 | 8.0 |

| BLD-94-075 | 7.5 | 263 | 303 | 36 | 8.0 |

| BLD-94-080 | 8.0 | 263 | 303 | 36 | 8.0 |

| BLD-94-085 | 8.5 | 295 | 339 | 40 | 10.0 |

| BLD-94-090 | 9.0 | 295 | 339 | 40 | 10.0 |

| BLD-94-095 | 9.5 | 327 | 371 | 40 | 10.0 |

| BLD-94-100 | 10.0 | 327 | 371 | 40 | 10.0 |

All Dimensions in MM

PROCEDURE :

- Machine a pilot hole with an m7 toleranced series drill to a minimum pilot depth of 1 to 1.5 x D.

- Enter the pilot hole at a speed of approx. 300 RPM, and with a feed rate of approx. 19 - 20 IPM

- Start high coolant pressure and increase RPM.

- Continuous drilling to complete hole depth without peck cycle.

- For through holes with oblique exit, reduce the feed rate to 40% approx. 1 mm prior to break-through.

- After reaching hole depth reduce machine spindle RPM and withdraw.

Also offered on request in :

- Inches sizes and intermediate sizes.

- Specific tolerances.

- Drill point geometry to suit application.

- Flute design to suit application.

- Special coatings to enhance tool life.

- Special shank (Weldon, whistle notch etc.)